Expert Picks For Tuck Pointing Products That Deliver Precision

Get the right tools and materials to achieve professional-quality tuck pointing with ease and confidence.

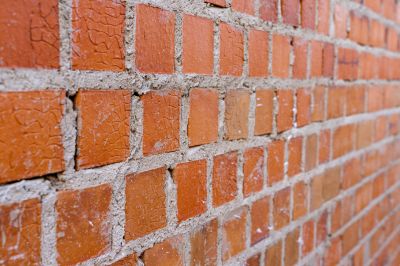

Tuck pointing is a specialized masonry technique used to repair and restore the appearance and integrity of brickwork and stone structures. This process involves removing deteriorated mortar from the joints and replacing it with fresh mortar that matches the existing in color and texture. Proper tuck pointing can enhance the aesthetic appeal of a building while also protecting it from water infiltration and structural damage. Whether undertaking a small repair or a large restoration project, selecting the right products is essential for achieving durable and visually appealing results.

Tuck pointing is a specialized masonry technique used to repair and restore the appearance and integrity of brickwork and stone structures. This process involves removing deteriorated mortar from the joints and replacing it with fresh mortar that matches the existing in color and texture. Proper tuck pointing can enhance the aesthetic appeal of a building while also protecting it from water infiltration and structural damage. Whether undertaking a small repair or a large restoration project, selecting the right products is essential for achieving durable and visually appealing results.

Top Overall Option

Multi-Function Masonry Tuck Pointing Kit

This comprehensive kit offers a range of manual tools, including trowels, joint rakers, and chisels, designed for precise mortar removal and application. It also includes a selection of mortar mixing paddles and color-matching compounds to ensure seamless repairs. Ideal for both DIY enthusiasts and professionals, this kit provides versatility and durability for various tuck pointing tasks.

Types of Products For Tuck Pointings

Manual Trowels

Essential for applying and shaping mortar, manual trowels come in various sizes and shapes to suit different joint depths and finishes.

Joint Rakers

Tools designed to remove old mortar from joints, available in different widths for precise cleaning.

Pointing Chisels

Used for removing deteriorated mortar and preparing joints for new mortar application.

Mortar Mixers

Power or manual mixers that facilitate the preparation of consistent mortar batches.

Color-Matching Mortar

Pre-blended or custom-mixed mortars that match existing masonry colors for seamless repairs.

Mortar Bags and Guns

Applicators that allow for precise placement of mortar into joints, suitable for detailed work.

Sealants and Water Repellents

Protective coatings that help seal repaired joints and prevent water penetration.

Mortar Color Stains

Stains used to match or accentuate mortar joints for aesthetic purposes.

Power Grinders and Sanders

Tools for removing excess mortar or smoothing surfaces before repair.

Brushes and Sponges

Used for finishing mortar joints and cleaning surfaces after application.

Popular Choices

Complete sets that include essential tools and materials for tuck pointing projects, suitable for DIYers.

Adjustable tools that accommodate various joint sizes for efficient mortar removal.

Designed for comfortable handling during extended use, available in various blade shapes.

Pre-mixed or customizable options that offer reliable workability and durability.

Tools that facilitate clean and controlled mortar application in tight joints.

Ready-to-use pastes for quick color matching and aesthetic repairs.

Platforms for mixing and holding mortar during application.

Sprays that provide a protective barrier after tuck pointing is complete.

Tools for smoothing and finishing mortar joints for a professional look.

Compact mixers suitable for small to medium repair projects.

The tools and materials used in tuck pointing vary widely, from manual hand tools to advanced power equipment. Masonry trowels, pointing chisels, and joint rakers help in removing old mortar and shaping new joints. For applying mortar, different types of pointing guns and caulking tools enable precise placement. Additionally, specialized mortar mixes, color-matching compounds, and sealants are available to ensure the finished work blends seamlessly with existing masonry. Choosing the appropriate products depends on the specific needs of the project, the type of masonry, and the desired finish.

In recent years, innovations in masonry tools have made tuck pointing more efficient and accessible for both professionals and DIY enthusiasts. Ergonomic designs, adjustable features, and high-quality materials contribute to ease of use and longevity. Proper preparation, along with the right selection of tools and materials, can significantly influence the durability and appearance of the repair. It is also important to consider weather conditions and the compatibility of mortar mixes to ensure the longevity of the tuck pointing work.

Ultimately, investing in the right products for tuck pointing can help achieve a professional-looking finish that preserves the structural integrity of masonry surfaces. Whether working on historic buildings or modern facades, the right tools and materials enable effective repairs and restorations. Careful selection and proper technique are key to ensuring that the work not only looks good but also stands the test of time.

Key Buying Considerations

- Type of masonry surface and compatibility with repair products

- Project size and whether a complete kit or individual tools are needed

- Ease of use and ergonomic features for prolonged work

- Durability and quality of tools to withstand repeated use

- Color-matching capabilities for seamless aesthetic integration

- Weather conditions and timing for application to ensure proper curing

- Type of mortar mix suitable for the specific brick or stone type

- Precision and control offered by applicators and pointing guns

- Cleaning and maintenance requirements for tools

- Compatibility of sealants and water repellents with existing masonry materials

- Budget considerations and value for money

- Availability of replacement parts or additional accessories

- Recommendations for professional versus DIY use

- Environmental conditions that could affect mortar setting and adhesion

- Safety features and protective gear recommendations

This page contains affiliate links. We may earn a commission if you purchase through these links, at no additional cost to you.